3D printers in its place use additive manufacturing systems. They just take 3D product facts and import it into a 3D slicer, which slices the element into layers to the 3D printer to deposit product or selectively solidify resin or powder to develop the concluded portion.

As much less heat is utilized during the h2o jet cutting method than most other CNC kinds, it is commonly accustomed to Minimize materials that could otherwise have their Qualities improved by heat. The procedure is likewise incredibly exact, and is helpful for very intricate carving and cutting.

3D printing is considered ideal for very brief operate, intricate components with elaborate geometries, with CNC better for quicker, less costly sections in metal, Wooden or other tricky supplies.

It controls the depth and orientation from the tools, making sure smooth and accurate cuts. This system functions in coordination Using the servo motor, which makes it a vital element in analyzing the quality of the finished item.

With a chance to rotate on both of those horizontal and vertical axes concurrently, they can accessibility almost any Component of a workpiece easily.

Phase four: Immediately after this, the operator trials the G-code or other plan to look for any clear faults, ahead of jogging the machining Procedure.

Have you been interested in the cutting-edge globe of CNC Machining Centers? Dive in the realm of precision engineering and advanced manufacturing with us as we take a look at what a machining center is, its many kinds, vital parts, purposes, and the benefits and drawbacks of employing this revolutionary technology. Let's embark on a journey to uncover the fascinating capabilities of CNC machining centers!

Adaptability at any time due to an array of factors to suit your requirements like rotary and tilting tables

Machining centers are Outfitted with overload safety equipment and wear detectors Shop now to monitor tool use and machine overall performance. These sensors detect irregular problems, including Instrument breakage or too much load, and provide alerts to forestall potential problems.

The APC system includes a number of pallets that may be preloaded with raw substance, enabling for uninterrupted machining. This automation significantly enhances production efficiency, lessening manual managing and glitches.

User interface: Operators input the G-code in the machine’s control panel. Modern day machining centers typically characteristic person-welcoming interfaces for simpler Handle.

Deliver us One more enterprise’s estimate in your horizontal or vertical machining center's spindle cartridge mend - if we will’t be competitive, we’ll provide you with a $fifty copyright card.

In advance of CNC existed, there was only NC. This suggests Numerical Handle (with no “C” of Laptop or computer), the place again while in the fifties punched tape was utilized to manually input commands on to information cards to explain where to maneuver the machine and tools to chop areas. This was far slower, less efficient, plus much more susceptible to human mistake.

By knowledge how these elements function jointly, makers can enhance their production procedures and attain higher levels of productivity. It's important to take into account Each individual part's capabilities and maintenance prerequisites To optimize the general performance on the machining center.

Ross Bagley Then & Now!

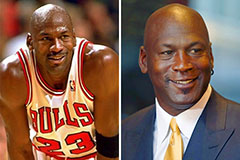

Ross Bagley Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now!